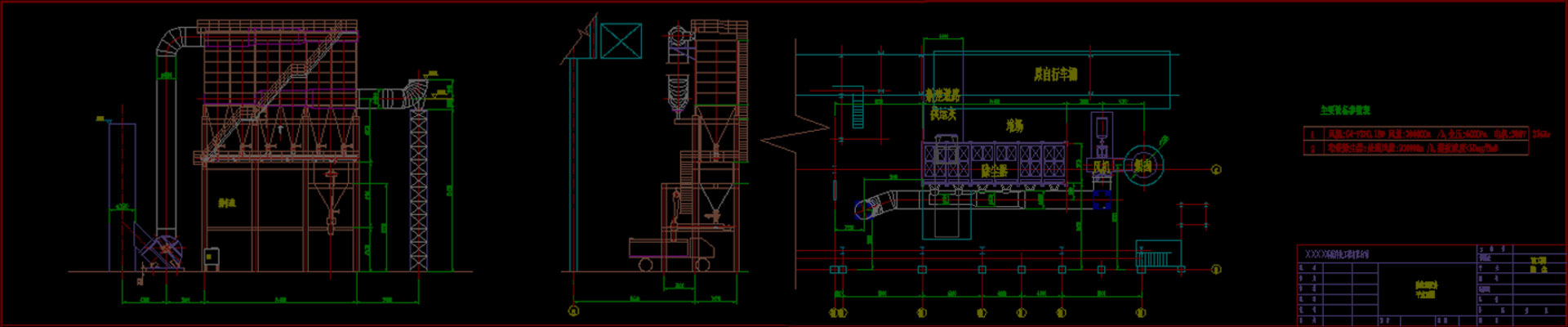

01 Site Assessment & Foundation Construction:

Select level ground with ≥5t/m² bearing capacity, align with process flow requirements

Cast concrete foundation (C25 grade) with anchor bolts, verify horizontal error ≤3mm

Select level ground with ≥5t/m² bearing capacity, align with process flow requirements

Cast concrete foundation (C25 grade) with anchor bolts, verify horizontal error ≤3mm

Assemble steel frame with anti-corrosion bolts (M16), verticality tolerance ≤1‰ height

Install hopper with 3mm asbestos sealing rope at flange joints

Insert PTFE filter bags gently into tube sheet holes, secure with spring tension rings

Maintain 5mm gap between filter bags and cages to prevent abrasion

Mount air tank (1.5× design pressure tested) and align nozzles (±2mm to bag centers)

Label pulse valves (0.5-0.7MPa operating range) for maintenance traceability

Connect inlet/outlet ducts with 3mm rubber gaskets, bolt tightening torque ≥45N·m

Conduct smoke leakage test (≤2% leakage rate) at welds and access doors

Wire PLC cabinet (IP54 rated) with differential pressure sensors (0-2500Pa range)

Verify grounding resistance ≤4Ω and motor phase sequence

Activate pulse cycles (15-30s intervals) and monitor fan bearing temperature (≤80°C)

Adjust damper openings to maintain 800-1500Pa system pressure drop

Issue inspection certificate (GB 16297-2025 compliance) with ≥99.5% efficiency data

Submit as-built drawings and O&M manuals with lubrication schedules